GIESSARM FGA500

POSSIBLE VARIATIONS: HYDRAULIC / FULLY ELECTRIC

- Max. working range per side: up to 4.30 m (including water jet)

- Working height: 0 – 3.10 m

- Innovative swivel movement via special gear joint arrangement

- Swivel range: approx. 250

- Swivel right/left: 125° each

- Swivel angle of casting head: 170° (electrically adjustable)

- Main arm can be tilted by 55

- Side arm can be swivelled by 150

- Main and secondary arms, pipes and gear components made of stainless steel

- Parking device with 2 crank supports and 4 wheels (2 of which are braked)

- Can be attached regardless of the height of the vehicle's mounting device

- Can be attached to any mounting device (vehicle plate, three-point linkage, etc.) and to all vehicle and tractor types – no lifting gear required on the vehicle

- Can be attached and removed by one person

- Compact transport position thanks to low front dimension

- Weight: approx. 110 kg

GIESSARM FGA700

POSSIBLE VARIATIONS: HYDRAULIC / FULLY ELECTRIC

- Max. working range per side: up to 5.30 m (including water jet)

- Working height: 0 – 4.10 m

- Innovative swivel movement via special gear joint arrangement

- Swivel range: approx. 250°

- Swivelling right/left: 125° each

- Swivel angle of casting head: 170° (electrically adjustable)

- Main arm can be tilted by 55

- Side arm can be swivelled by 150

- Main and secondary arms, pipes and gear components made of stainless steel

- Parking device with 2 crank supports and 4 wheels (2 of which are braked)

- Can be attached regardless of the height of the vehicle's mounting device

- Can be attached to any mounting device (vehicle plate, three-point linkage, etc.) and to all vehicle and tractor types – no lifting gear required on the vehicle

- Can be attached and removed by one person

- Compact transport position thanks to low front dimension

- Weight: approx. 120 kg

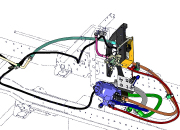

GIESSARM FGA1000

POSSIBLE VARIATIONS: HYDRAULIC / FULLY ELECTRIC

- Max. working range per side: up to 7.50 m (including water jet)

- Working height: 0 – 5.00 m

- Innovative swivel movement via special gear joint arrangement

- Swivel range: approx. 250°

- Swivel right/left: 125° each

- Swivel angle of casting head: 170° (electrically adjustable)

- Main arm can be tilted by 55

- Side arm can be swivelled by 150

- Main and secondary arms, pipes and gear components made of stainless steel

- Parking device with 2 crank supports and 4 wheels (2 of which are braked)

- Can be attached regardless of the height of the vehicle's mounting device

- Can be attached to any mounting device (vehicle plate, three-point hitch, etc.) and to all vehicle and tractor types – no lifting gear required on the vehicle

- Can be attached and removed by one person

- Compact transport position thanks to low front dimension

GIESSARM FGA1200

POSSIBLE VARIATIONS: HYDRAULIC / FULLY ELECTRIC

- Max. working range per side: up to 8.50 m (including water jet)

- Working height: 0 – 6.00 m

- Innovative swivel movement via special gear joint arrangement

- Swivel range: approx. 250°

- Swivel right/left: 125° each

- Swivel angle of casting head: 170° (electrically adjustable)

- Main arm can be tilted by 55

- Side arm can be swivelled by 150

- Main and secondary arms, pipes and gear components made of stainless steel

- Parking device with 2 crank supports and 4 wheels (2 of which are braked)

- Can be attached regardless of the height of the vehicle's mounting device

- Can be attached to any mounting device (vehicle plate, three-point linkage, etc.) and to all vehicle and tractor types – no lifting gear required on the vehicle

- Can be attached and removed by one person

- Compact transport position thanks to low front dimension

The comfort watering arm with a range of up to 8.50 m

Set new standards in municipal and commercial plant care with the Fiedler watering arm. Our watering arms, made entirely of high-quality stainless steel, combine durability with state-of-the-art control technology. With an impressive reach of up to 8.50 m (including water jet), you can easily reach even remote green areas. The 250° swivel range provides an enormous working radius in front of the vehicle, allowing you to water areas directly next to the driver's or passenger door without having to manoeuvre.

No hydraulics? No problem! We think ahead: in addition to classic hydraulic versions, we offer the first fully electric watering arm for all municipal vehicles.

Intelligent control with the FIEDLER FMC

Forget jerky movements. Our proportional CAN-BUS control system guarantees smooth workflows without lag.

The award-winning FIEDLER FMC control system offers you, among other things:

- Precise dosing: flow rate (l/min) or exact individual dispensing at the touch of a button.

- Automation: Save spray arm positions, which the system then moves to fully automatically.

- Relief: Numerous automatic programmes support the driver and increase work safety.

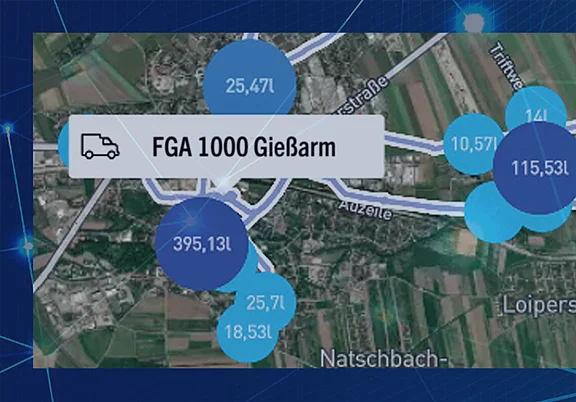

Digital management –

Watering records and route planning

Digitise your workflows with our optional data collection feature. The system proactively supports you in resource planning:

- Planning: Optimise your routes and application rates in advance on your PC.

- Documentation: Create legally compliant pouring records at the touch of a button.

Evaluation: Access all performance data immediately after the route – for maximum transparency towards clients.

Maximum irrigation range:

Long-range nozzles for maximum flexibility

Want to maximise your range when watering large areas? Our state-of-the-art long-range nozzles offer the ideal solution – even in hard-to-reach areas.

Precise control and maximum flexibility

Installation is tailored to your needs: either on the left, right or both sides of the tank system. Thanks to the intuitive joystick control, the nozzles can be operated just as conveniently and precisely with the FMC as our proven watering arm.

Technical highlights for your land management:

- Large swivel range: Benefit from maximum mobility with vertical angles from +21° to -17° and horizontal angles from +65° to -35°.

- Individual spray pattern: The spray pattern of the long-range nozzle can be adjusted in just a few simple steps.

- Quick-change system: The integrated C-connection allows you to change different nozzle attachments easily and quickly.

- Synergy effect: In combination with our watering arm, you are well equipped for all the challenges of modern irrigation technology.

Your advantage: Effortlessly reach remote plants and green areas with minimal time and maximum efficiency.

The Fiedler single-tank strategy –

Systematic year-round use

Maximise the profitability of your vehicle fleet. With the FTS tank system (AllSeason-FlexiTank), you can use your carrier vehicle 365 days a year:

- Summer use: Ideal for watering, flushing and high-pressure cleaning. Optionally expandable as a hot water system for chemical-free weed control.

- Winter use: In just a few simple steps, you can convert the system into a highly efficient brine spray system for winter service.

Invest in sustainability and efficiency. Fiedler watering arms are the robust answer to the challenges of modern urban and landscape maintenance.

10 most important FAQs about watering arms

A watering arm (also known as a watering boom or irrigation arm) is a professional attachment for municipal vehicles such as Unimogs, Multicars, tractors or lorries. It is used for the efficient mobile watering of trees, green spaces, hanging baskets and traffic islands. The key advantage is that the driver controls the arm directly from the cab without having to get out or pull heavy hoses.

The use of a FIEDLER pouring arm significantly increases work safety and efficiency:

- One-man operation in flowing traffic: No second employee is required to remain in the danger zone of the road.

- Obstacle clearance: The arm easily reaches over parked cars, fences or crash barriers.

Ergonomics: No heavy lugging of hoses; convenient control via joystick from the driver's seat.

The main difference lies in the superior mobility and future-proof drive technology. While many market standard models often only cover a range of 160° to 210°, the FIEDLER casting arm has a swivel range of approx. 250° as standard . In addition to classic hydraulics, we also offer a fully electric control system that enables more precise movements .

Depending on the variant, operation is via the vehicle control system or a CAN-BUS joystick with colour display (FMC).

- Control: Optionally hydraulic or fully electric for sensitive movements.

Plant protection: The large shower head produces a soft, low-pressure spray ("soft rain"). The water quantity and spray intensity can be precisely adjusted on the control unit to protect young plants and avoid wasting water.

No, not necessarily. We offer two drive concepts:

- Variant A (hydraulic): Uses the existing vehicle hydraulics.

- Variant B (fully electric): This version operates completely independently of the hydraulics. This makes it the perfect solution for electric municipal vehiclesor vehicles that have no or insufficient hydraulic systems of their own.

Yes. With FIEDLER Connect, we offer a modern telematics solution to meet the increasing documentation requirements for local authorities:

- Real-time monitoring of work.

- Legally compliant digital proof of watering for the quantities of water applied.

- Order planning and customer management directly via the system.

![[Translate to english:] Sickle mowers](/fileadmin/_processed_/8/c/csm_vorschaubild_FFS_3282ae4150.jpg)

![[Translate to english:] Tank systems](/fileadmin/_processed_/6/6/csm_fts_vorschaubild_991af2d481.jpg)

![[Translate to english:] Tank trailer](/fileadmin/_processed_/c/9/csm_FTS_vorschau_18932b6c85.jpg)

![[Translate to english:] Watering arm](/fileadmin/_processed_/5/c/csm_FGA-vorschaubild_4b6f0c9396.jpg)

![[Translate to english:] Washing boom](/fileadmin/_processed_/e/3/csm_FSB_vorschaubild_201a2a4cfe.jpg)

![[Translate to english:] Scrubbing Deck Brush](/fileadmin/_processed_/8/c/csm_FSD_vorschaubild__2dd8e0f1de.jpg)

![[Translate to english:] Washing brush](/fileadmin/_processed_/3/3/csm_FWB_vorschaubild_ec78bb85fc.jpg)

![[Translate to english:] Sewer flusher](/fileadmin/_processed_/6/9/csm_vorschaubild_kanalspueler_2376f176a9.jpg)

![[Translate to english:] Front sweeping machines](/fileadmin/_processed_/2/e/csm_FKM_vorschaubild_baa60a82de.jpg)

![[Translate to english:] Weed brush](/fileadmin/_processed_/7/3/csm_fwk_vorschaubild_737717a7b3.jpg)

![[Translate to english:] Hot water system](/fileadmin/_processed_/5/2/csm_ftskombi_vorschaubild_3b0e8d5e7f.jpg)

![[Translate to english:] Weed brush](/fileadmin/_processed_/c/7/csm_FUV-vorschaubild_34df2a5752.jpg)

![[Translate to english:] foliage & waste aspiration](/fileadmin/_processed_/e/3/csm_FLAS_vorschaubild_675f23f59a.jpg)

![[Translate to english:] Container systems](/fileadmin/_processed_/c/f/csm_container_fsc_58e2818af0.jpg)

![[Translate to english:] Snow ploughs / full mouldboard foldable plough](/fileadmin/_processed_/8/5/csm_FRS-vorschaubild_2_a6af3349f6.jpg)

![[Translate to english:] Spring flap plough](/fileadmin/_processed_/9/5/csm_FRS-vorschaubild_191c662338.jpg)

![[Translate to english:] Wedge-shaped plough](/fileadmin/_processed_/6/0/csm_webseite-vorschaubild_eaa02f6fd8.jpg)

![[Translate to english:] Clearing / Sweeping Unit](/fileadmin/_processed_/e/2/csm_FRK_vorschaubild_dd6912ef49.jpg)

![[Translate to english:] Brine sprayer](/fileadmin/_processed_/3/7/csm_FSSA_Vorschau_531cbad5c2.jpg)

![[Translate to english:] Attachment spreader](/fileadmin/_processed_/d/c/csm_FWS-vorschaubild_de11754d00.jpg)

![[Translate to english:] Chassis-mounted spreader](/fileadmin/_processed_/b/e/csm_FSS_vorschaubild_6c6dd9041e.jpg)

![[Translate to english:] Brine mixing plant](/fileadmin/_processed_/1/1/csm_FSMA_vorschaubild_e32f10e853.jpg)

![[Translate to english:] Universal front lift](/fileadmin/_processed_/5/8/csm_FUF_vorschaubild_9e5a112cfd.jpg)

![[Translate to english:] Rear blower](/fileadmin/_processed_/7/4/csm_FHG_menue_6cdd000772.jpg)

![[Translate to english:] Adapter plates](/fileadmin/_processed_/4/7/csm_Adabterplatte_5c2ac30b03.jpg)

![[Translate to english:] Control panels](/fileadmin/_processed_/a/1/csm_Bedienpulte_79c6d27fcc.jpg)

![[Translate to english:] Lamp holder](/fileadmin/_processed_/e/3/csm_Lampentraeger_01_144be172f2.jpg)

![[Translate to english:] Data collection](/fileadmin/_processed_/5/d/csm_Datenerfassung_2c1bbc88e1.jpg)